Clean coal briquettes means using the selected low sulfur low volatile pulverized anthracite (or semi-coke), through sieving, crushing, adding a certain proportion of adhesive ,combustion improver, desulfurizer and waterproof additive etc, then through a mixing machine, fully mixing together, pressed into difform briquettes by Zhongzhou clean coal briquette machine , roller cold pressed type, the briquettes is with a certain intensity, can meet the government emission standards , sulfur content below 0.4%, volatile below 12%, ash content below 24%, the water is less than 4%, at the same time keep the calorific value of 5740 kcal or more. It is estimated that the saving rate of clean briquetted coal is more than 20% (if tuse the special coal stove, coal saving rate will be more than 30%), sulfide and toxic gas emissions reduced more than 70%, soot emissions reduced more than 80%.

Promotion of clean coal briquettes is mainly in order to reduce air pollution, improve the utilization rate of coal combustion.

Making clean coal briquettes by ZHONGZHOU clean cal briquette machine(civilian):

1. The main raw materials: bituminous coal, anthracite coal, semi-coke.

2. Accessories: a variety of organic additives (binder, modifier etc.).

3. Features: more inflammable than anthracite, clean and smokeless, high calorific value (5300~6000 calories), environmental protection.

4. Product performance characteristics: good reliability, production can be controlled well.

5. Price: cheap (900~950 RMB / Ton), as the main raw material is a by-product of semi-coke which is from at the end of the dry distillation of bituminous coal, the price is cheap.

6. packaging: 25 kg standard woven bag packaging.

7. Logistics: it is easy to close packed transportation to solve the dust pollution in the process of logistics.

8. Promotion: since the clean coal briquettes is from sufficient raw materials, cheap, clean, environmentally friendly products, reliable performance,production controlled, it will the ideal product that replaced powder coal burning in near the future.

Making squared coal briquettes (civil central heating, industrial use)

1. Main raw materials: all kinds of low quality coal, raw material sufficient.

2. Accessories: a variety of additives (such as: sulfur fixing agent, binder, modifier, etc.).

3. Squared coal briquette features: clean, smoke-free, environmental protection, low calorific value (usually less than 4000 calories), product performance characteristics: production reliability.

4. Price: super cheap (450~500 RMB / Ton), highly competitive.

5. Packaging: carton packaging.

6. Logistics: easy to close packed transportation.

7. Shortcomings: the need for special stove, the stove only can heating, not cooking.

8. Promotion: it is the most ideal briquettes as heating, cheap price, easy production and environmental protection, production controlled, adequate raw materials.

Clean coal briquettes has six advantages:

1. It is easy to burning,has high calorific value, is two times than the calorific value of traditional bulk coal, greatly reducing coal consumption.

2. It production safety, it has no black smoke, no odor, very low harm to the human body.

3. It is more convenient.

4. It is more environmental friendly, clean coal briquettes has no dust when burning, less harmful, low sulfur content, not cause air pollution;

5. It is more energy saving, the comprehensive energy efficiency is more than 50% in the combustion;

6. It is more economical.

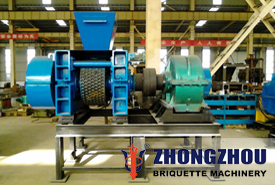

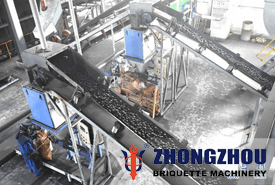

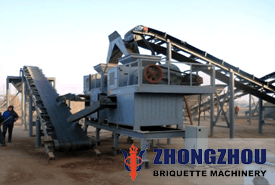

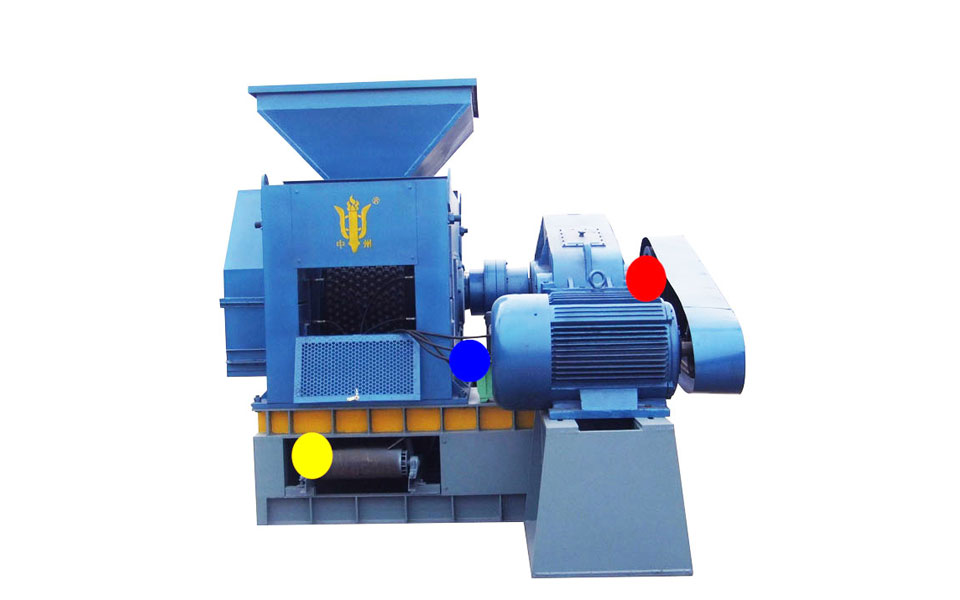

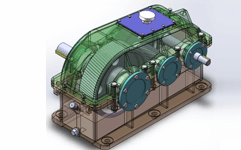

The clean coal briquette machine we produced is specifically designed for briquetting clean coal ,semi-coke materials, it has high productivity, high degree of automation, production efficiency,low failure rate, easy maintenance, so Zhongzhou clean coal briquette machine was welcomed by many enterprises at home and abroad to explore, mutual benefit and win-win.

| Model Performance | ZZXM-4 | ZZXM-6 | ZZXM-8 | ZZXM-10 | ZZXM-15 | ZZXM-20 | ZZXM-30 | ZZXM-40 |

| Output | 3-4t/h | 6t/h | 8t/h | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h |

| Roller width | 250mm | 240mm | 220mm | 300mm | 336mm/400mm | 428mm/500mm | 500mm | 00mm |

| Roller diameter | 360mm | 400mm | 450mm | 500mm | 650mm | 750mm | 850mm | 1000mm |

| Power | 7.5 kW | 11 kW | 18.5kW | 22kW | 37kW | 55kW | 90 kW | 110kW |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ500 | ZQ650 | ZQ850 | ZQ1000 | ZQ1000 |

| Pressure type | Mechincal | Mechincal | Mechincal | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Roller material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn |

| 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | |

| wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | |||||

| Roller assemble | Split-clamp type | Temper assembly | Temper assembly | |||||

| Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC |

| Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | |||||

| Dimension (mm) | 1200x1150x1835 | 1400x1298x2125 | 1700x1510x2200 | 2000x1960x2440 | 2188x1972x1670 | 2660x2300x1750 | 2965x2450x1980 | 3065x28850x2220 |

| Weight(kg) | 2100 | 2300 | 2750 | 5800 | 7600 | 9000 | 15500 | 25000 |

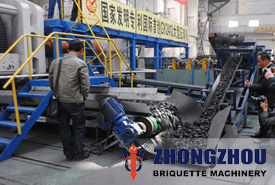

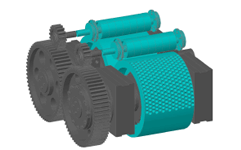

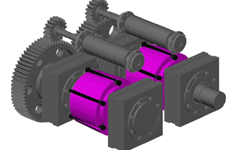

Four rollers double pressure

after the first pressurization, the materials between main and auxiliary rollers enter the place between two main rollers for a second pressurization, where the pressure will be twice of the type of two rollers.(the auxiliary roller pre-press the hemisphere on the amin roller to exhaust air, the hemisphere will be pressed again into briquettes fomation through two main rollers).

GB standard hydraulic components

manufaturing by Dezhou oil pump company, using embolism type pump equipped with storage device which can be operation of protection briquette machine when the hydraulic moment fluctuation, the oil cylinder adopts compound type and be made of standard material 27SiMn, extremely good finish, wear resistance, having protective effect on seals.

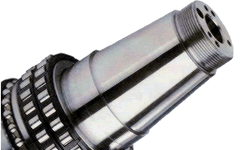

Roller taper assembly techology(patent)

Roller and wheel hub of briquette machine is processed into tamper structure, which shall be compacted firmly by bolts for stability and reliance, easy to replace roller,save time and efforts for users.

9Cr2 forging rollers

the roller materials adpot 9Cr2 forging steel, high precision and abrasion resisitant, the rigidity reach to 55-60HR through prempering.

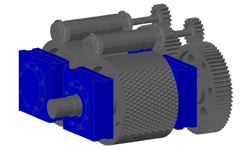

National standard bearing

Using the rolling mill bearing series, each model is the double row cylindrical ball bearing, well-known brands, lagre load bearing, stable performance, guarantee period of 5 years.

Split plummer block

Unique split type design, precision machining, simply remove the bolts when the user maintenance, open housing, can be seen bearing, ease of maintenance.

Steel reducer

Independent production, full steel material bell housing, gears made of 40Cr steel, stable performance.

Spindle material

high quality finished No.45 steel tempering.