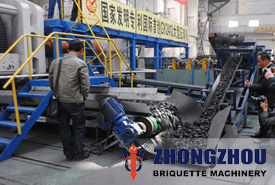

Zhongzhou hydraulic briquette machine/briquetting machine is mainly used to press lignite, coal, iron concentrate, aluminum powder, coke, iron oxide, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, other ore powder, widely used in refractories, metallurgy, chemical industry, power plants, energy, transportation, heating and other industries, the briquettes be pressed by hydraulic briquette machine/briquetting machine is energy saving and environmental protection, convenient transportation, improve the utilization rate of waste, with advantages of continuous production, high automation, good economic and social benefits.

There are two types of hydraulic briquette machine/briquetting machine in Zhongzhou company, one is standard hydraulic briquette machine, antoher one type is high pressure hydraulic briquette machine, customer should choose one of them depend on raw materials, some raw materials such as coal, lignite, iron scales, coke allow to be added some binder and water in briquetting process, it better choose standard hydraulic briquette machine to complete briquettes production, but some materials such as quicklime, magnesium, fluorite powder,aluminium powder not allow to add any water in process, it have to choose special hydraulic briquette machine to complete briquettes production, so when inquiry, customer should tell us your raw materials is, and if it allow to add water in process, Zhongzhou company will offer you a proper proposal. The complete of standard hydraulic briquette machine production line include hopper---crusher---feeder---mixer---briquette machine, and vertical dryer, here we sincerely state the process of standard hydraulic briquette machine prodction line as follows:

Statement of the Complete Output 2-50 T/H Briquettes Production Line

1. Rotary Dryer

Rotary dryer is widely used to dry humidity granularity materials in the industries of mineral dressing, building material, metallurgy and chemical, coal mine, etc. Wide supply scope and simple operation are the main features of it, materials should be dried to 3-10% water content that meet the demands of briquetting.

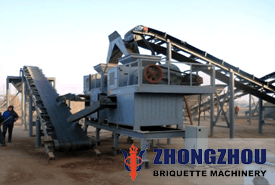

2. Two Stage Crusher:

Two stage crusher is designed and optimized in accordance with international latest crushing technology. It can crush all kinds of hard ore/metallurgy materials such as limestone, clinker, coal,coke,manganese, silica, iron ore, zinc oxide etc minerals in the metallurgy, mining, chemical industry. Its humidity of raw materials can be reach to 40%,the feeding size reach to 400mm, after crushing, the particle not more than 3mm to meet briquetting.

3. Hopper silo:

This is an automatic proportioning feeder which is used together with next mixer. It can automatically perform feed proportioning procedure according to the proportion setup pf customers so that improve working efficiency. That is composed of feeding unit, proportioning unit, electronic control system, etc.

4. Horizontal Two-shaft Mixer:

The horizontal two- shaft mixer mix materials continuously and uniformly. During the mixing, to add water and binder (liquid binder or powderd binder is considered by user's formula),controlling moisture in 8-15%,then the blended materials continuously go into briquette machine for briquetting by belt conveyor,

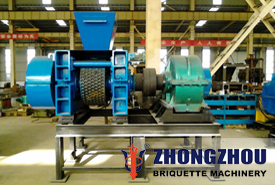

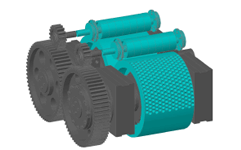

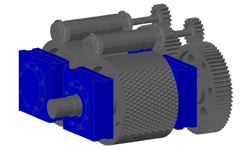

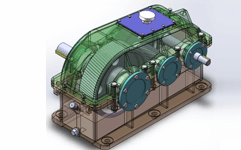

5. Hydraulic Briquette Machine:

Zhongzhou hydraulic briquette machine is a new patented type of briquetting machine, easy to operate, high pressure, work stably, energy conservantion, environmental friendly, easy for user to remove and install, mould can be produced in accordance with customer's requirements, the final briquettes has high hardness, high density, espcially the thermal intensity is high.

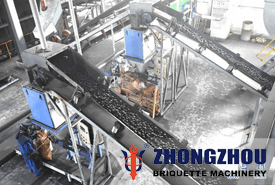

6. Vertical Dryer:

This is the professional equipment for drying briquettes, no matter coal briquettes, mineral briquettes,metallurgy briquettes, all can be dried by this vertical dryer, the moisture content of briquettes can be reduced to 3%, cause of briquettes came from briquette machine with 12% water content, using a drying equipment is necessary for a large scale project. Vertical dryer has the advantages of continuous production, small occupation area, low energy consumption, less parts, low failure, high yield, it is a customer preferred drying equipment.

7. Belt Conveyor:

This belt conveyor transfers material into every equipment, make the whole production line work continuously and automatically. It works under the temperature situation ranging from -20℃ to +40℃, the transferred material should be lower than 50℃.

8. Electric control cabinet

Its main role is for the all motors' start and stop control in the whole production line, under the special requirement it's also able to control the position of the motor and the speed, fault detection and fault diagnosis can be carried out when the motor is in fault, which is very convenient and quick.

Different materials will be designed different production solution, customer at the time of consultation need inform us of the materials' moisture, particle size, yield, briquettes size, shape, some special circumstances maybe need auxiliary equipment such as other types of crusher,other types of mixer,screen mesh, vibration sieve, binder feeder, liquid mixing tank, magnetic separator, electronic belt weigher, variable-frequency drive.

If you are interested in our other type high pressure briquette machine/briquetting machine, please consult with us ZHONGZHOU Machinery by e-mail or online E-MAIL: zzbriquettemachine@dzzzg.cn, TEL: +86-371-64597766 , Mobilephone: +86-13783550028.

Zhengzhou Zhongzhou Briquette Machinery Plant has formed a professional manufacturer on researching and developmenting, design and manufacture briquette machine in China, and equipped with the perfect test room of briquette machine/briquetting machine , our factory can determine the process process and process parameters, and complete the model selection and design and manufacture based on users' material through experiment, that is the most complete and specific briquette machine manufacturing base. Welcome to visit our factory!

| Model Performance | ZZXM-4 | ZZXM-6 | ZZXM-8 | ZZXM-10 | ZZXM-15 | ZZXM-20 | ZZXM-30 | ZZXM-40 |

| Output | 3-4t/h | 6t/h | 8t/h | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h |

| Roller width | 250mm | 240mm | 220mm | 300mm | 336mm/400mm | 428mm/500mm | 500mm | 700mm |

| Roller diameter | 360mm | 400mm | 450mm | 500mm | 650mm | 750mm | 850mm | 1000mm |

| Power | 7.5 kW | 11 kW | 18.5kW | 22kW | 37kW | 55kW | 90 kW | 110kW |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ500 | ZQ650 | ZQ850 | ZQ1000 | ZQ1000 |

| Pressure type | Mechincal | Mechincal | Mechincal | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Roller material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn |

| 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | |

| wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | |||||

| Roller assemble | Split-clamp type | Temper assembly | Temper assembly | |||||

| Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC |

| Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | |||||

| Dimension (mm) | 1200x1150x1835 | 1400x1298x2125 | 1700x1510x2200 | 2000x1960x2440 | 2188x1972x1670 | 2660x2300x1750 | 2965x2450x1980 | 3065x28850x2220 |

| Weight(kg) | 2100 | 2300 | 2750 | 5800 | 7600 | 9000 | 15500 | 25000 |

Four rollers double pressure

after the first pressurization, the materials between main and auxiliary rollers enter the place between two main rollers for a second pressurization, where the pressure will be twice of the type of two rollers.(the auxiliary roller pre-press the hemisphere on the amin roller to exhaust air, the hemisphere will be pressed again into briquettes fomation through two main rollers).

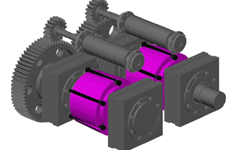

GB standard hydraulic components

manufaturing by Dezhou oil pump company, using embolism type pump equipped with storage device which can be operation of protection briquette machine when the hydraulic moment fluctuation, the oil cylinder adopts compound type and be made of standard material 27SiMn, extremely good finish, wear resistance, having protective effect on seals.

Roller taper assembly techology(patent)

Roller and wheel hub of briquette machine is processed into tamper structure, which shall be compacted firmly by bolts for stability and reliance, easy to replace roller,save time and efforts for users.

9Cr2 forging rollers

the roller materials adpot 9Cr2 forging steel, high precision and abrasion resisitant, the rigidity reach to 55-60HR through prempering.

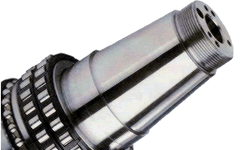

National standard bearing

Using the rolling mill bearing series, each model is the double row cylindrical ball bearing, well-known brands, lagre load bearing, stable performance, guarantee period of 5 years.

Split plummer block

Unique split type design, precision machining, simply remove the bolts when the user maintenance, open housing, can be seen bearing, ease of maintenance.

Steel reducer

Independent production, full steel material bell housing, gears made of 40Cr steel, stable performance.

Spindle material

high quality finished No.45 steel tempering.