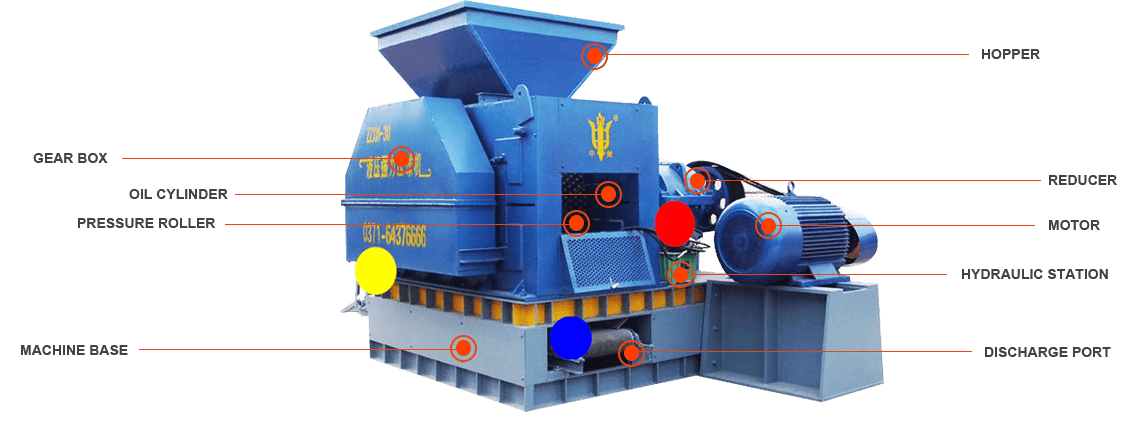

Main parts

Components

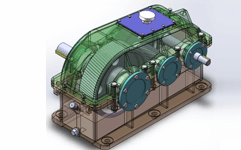

It mainly consists of a frame (or foundation support), reducer, drive- spindle seat, drive-spindle, driven shaft, main bearing, coupling, main roller, assistant- roller, wheel hub, drive gearing ,driven gearing, briquettes socket deviation adjuster, bearing seat, wedge assembly, oil cylinder, piston, oil pump, feeding hopper and unloading belt conveyor.

Main parts

4.Hydraulic station Hydraulic system diagram (Figure 1)

Hydraulic station makes use of DBD series oil pump, this pump combines with the pressure meter and various application valves to form an independent system.The hydraulic station offer machine enough pressure, keep work stably, safe in running and convenient for maintenance. ZHONGZHOU designed briquette machine that has dual-purpose of hydraulic and machanical pressure,become the first manufcturer controled this technology. The hydraulic and machanical pressure can be worked each other, when the machine can't work in cold winter or maintain hydraulic part, the machine can close the hydraulic part only work by its machanical pressure, in the normal, briquette machine run and work well by hydraulic pressure. In addition the accumulator set protect machine's pressure and loop when the pressure adruptly increased cause of feeding increased.

In order to meet the needs of combustion and smelting, usually the briquettes will be made into 20-80mm, their shape shall be around, elliptic, squared, pillowed and bread shape or customized.

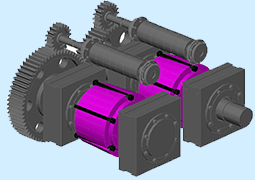

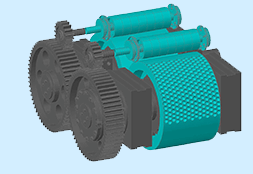

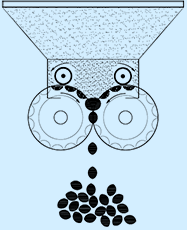

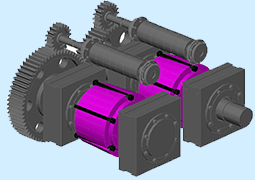

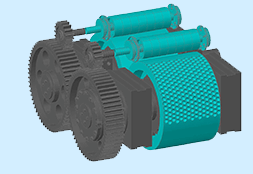

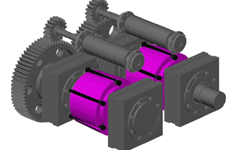

Four rollers double pressure

after the first pressurization, the materials between main and auxiliary rollers enter the place between two main rollers for a second pressurization, where the pressure will be twice of the type of two rollers.(the auxiliary roller pre-press the hemisphere on the amin roller to exhaust air, the hemisphere will be pressed again into briquettes fomation through two main rollers).

GB standard hydraulic components

manufaturing by Dezhou oil pump company, using embolism type pump equipped with storage device which can be operation of protection briquette machine when the hydraulic moment fluctuation, the oil cylinder adopts compound type and be made of standard material 27SiMn, extremely good finish, wear resistance, having protective effect on seals.

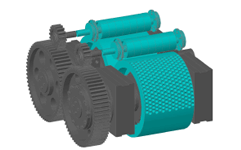

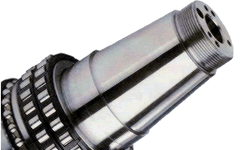

Roller taper assembly techology(patent)

Roller and wheel hub of briquette machine is processed into tamper structure, which shall be compacted firmly by bolts for stability and reliance, easy to replace roller,save time and efforts for users.

9Cr2 forging rollers

the roller materials adpot 9Cr2 forging steel, high precision and abrasion resisitant, the rigidity reach to 55-60HR through prempering.

National standard bearing

Using the rolling mill bearing series, each model is the double row cylindrical ball bearing, well-known brands, lagre load bearing, stable performance, guarantee period of 5 years.

Split plummer block

Unique split type design, precision machining, simply remove the bolts when the user maintenance, open housing, can be seen bearing, ease of maintenance.

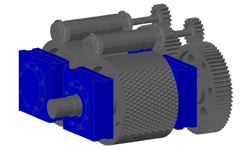

Steel reducer

Independent production, full steel material bell housing, gears made of 40Cr steel, stable performance.

Spindle material

high quality finished No.45 steel tempering.

ZHONGZHOU briquette machine also known as briquetting machine, briquette making machine,coal briquette machine, ball press, or briquette press,but in China people always call it briquette machine.This briquette machine is mainly used for various mining material, metallurgical materials , industrial wastes etc such as coal,coal slurry,bitumite, lignite, brown coal,coke powder, steel slag,bag filters dust,furnace flue dust ,manganese, mill scales, carbon black......

Making briquettes of diverse coal fines, coke breeze, coal slurry and middling coal, the briquettes are used for industrial boilers and civil furnaces.

Making briquettes of fine materials of non-ferrous metal and ferrous metal mineral to re-smelting in metallurgy industry, such as laterite nickel ore, alum ore, manganese ore, furnace dust, steel slag, mineral waste residue, carbon black, copper powder, magnesium, alumina,iron ore concentrate, manganese ore, silicon manganese alloy materials and so on.

Drying powder briquette machine can be used for quicklime, magnesium metal, furnace dust, aluminum as etc the raw materials which not allow to add any water in process; otherwise, it shall adopt wet model briquette machine, cause the dry powder briquette machine has higher consumption than the wet powder briquette machine as well as high purchase costs.

Making briquettes of desulfurized gypsum generated in thermo-eletric plants, which can be used for the cement production (using wet model briquette press for easy to de-mouding).

Making briquettes of coal dust in chemical and fertilizer industries, replacing lump coal for gas production, which save costs and increase economic benefits. Making briquettes of coal dust to replace lump coal in lime factories, building material and chemical industry, it can save cost; making briquettes of coal dust in ceramics factories, glass factories and coal- gas generator, replacing lump coal to save cost.

Making briquettes of coal dust to replace lump coal in lime factories, building material and chemical industry, it can save cost; making briquettes of coal dust in ceramics factories, glass factories and coal- gas generator, replacing lump coal to save cost.

Making briquettes of refractory materials in refractory industry.

The all materials in different industries needed to be smelted in kiln shall be completed by briquette machine.

Any change of technical data shall not be advised additionally.

| Model | ZZXM-4 | ZZXM-6 | ZZXM-8 | ZZXM-10 | ZZXM-15 | ZZXM-20 | ZZXM-30 | ZZXM-40 | Instruction |

| Performance | |||||||||

| Output | 3-4t/h | 6t/h | 8t/h | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h | According to material |

| Roller width | 250mm | 240mm | 220mm | 300mm | 336mm/400mm | 428mm/500mm | 500mm | 00mm | |

| Roller diameter | 360mm | 400mm | 450mm | 500mm | 650mm | 750mm | 850mm | 1000mm | |

| Power | 7.5 kW | 11 kW | 18.5kW | 22kW | 37kW | 55kW | 90 kW | 110kW | |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ500 | ZQ650 | ZQ850 | ZQ1000 | ZQ1000 | standard configuration |

| Pressure type | Mechincal | Mechincal | Mechincal | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | patent |

| Roller material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | Casting |

| 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | 9Cr2 | Forging | |

| wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | patent | |

| Roller assemble | Split-clamp type | Split-clamp type | Split-clamp type | Temper assembly | Temper assembly | Temper assembly | Temper assembly | Temper assembly | patent |

| Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | |

| Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | patent (four rollers) |

| Dimension (mm) |

1200x1150x1835 | 1400x1298x2125 | 1700x1510x2200 | 2000x1960x2440 | 2188x1972x1670 | 2660x2300x1750 | 2965x2450x1980 | 3065x28850x2220 | |

| Weight(kg) | 2100 | 2300 | 2750 | 5800 | 7600 | 9000 | 15500 | 25000 |

1. Feeding part Some raw materials are very light and can't be pressed into hardness briquettes, we design the assistant-rollers which work with the forming main rollers, it is the four rollers double press what we said, also this technology is one of our patents.

2. Driving part The driving system is: motor—V belt-- cylinder gear speed reducer—exposed gear—roller.

3. Forming part The forming part is a core of briquette machine, the materials of roller is such important for the quality of the whole machine. Three kinds of materials roller we produced:

65Mn manganese precision casting (economy)

Forging 9Cr2 (patent)

Wearing proof alloy (patent)

The forging 9Cr2 roller is advantageus because of its high density, solid structure, good abrasion resistance, long service life, nice manufacturability of processing trough, operation safety, this materials roller is widely used for large and medium briquette machine, of couse its cost is a little high. The precision casting wearing proof alloy roller presently is most wearable and longest work so far,through the technical improvement, it's more convenient to be assembled, replaced and maintenance, even reduce maintenance difficulty.